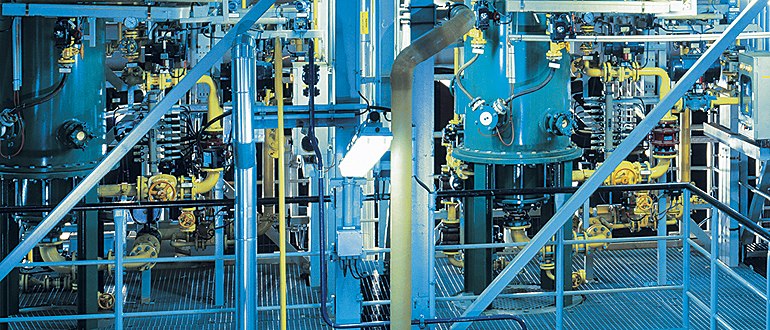

SGL Group’s bottom-fired HCl synthesis units are tailor-made turn-key solutions for hydrochloric acid production and anhy- drous HCl gas generation at highest levels of product purity. In our units, H2 and Cl2react at temperatures above 2000 °C (3630 °F) to produce HCl gas. In order to produce hydrochloric acid the gas is absorbed in water by a falling film absorber. Residual gas is cleaned in a vent gas scrubber.

The sophisticated design of our units results in highest product quality, highest efficiency, lowest maintenance requirements and highest up-times in the industry. By placing the burner at the bottom of the unit and positioning the absorption process in the upper section we can reduce the free chlorine content in the product. Condensates are drained separately, thus pre- venting product contamination.

Using bottom-burner technology also enables us to offer

the most compact and efficient synthesis in the market by integrating the scrubber section in the unit and implementing counter-current absorption. Furthermore, we can eliminate the need for pumps and buffer-tanks due to the elevated position of the product outlet nozzle. Maintenance tasks like burner flushing can be performed during operation. Addi- tionally, material degeneration and consequently the need for capital investment in spare parts is minimized.